INTRODUCTION TO INDUSTRIAL AUTOMATION WORKSHOP

IF YOU ARE FRESHLY GRADUATED STUDENT AND WANT TO PENETRATE YOUR WAY EASILY THROUGHT THE INDUSTRY, OR IF YOU ARE AN EXPERIENCED ENGINEER AND WANT TO ACQUIRE MORE PRACTICAL SKILLS, START TODAY AND JOIN US IN BUILDING A STRONG COMMUNITY WHERE WE SHARE OUR INDUSTRIAL EXPERIENCE WITH YOU FOR A BETTER ENGINEERING SOCIETY.

INTRODUCTION TO INDUSTRIAL AUTOMATION WORKSHOP

INDUSTRIAL AUTOMATION (AUT01)

- START DATE: FRIDAY 24TH OF JUNE 2022

- END DATE: MONDAY 25TH OF JUNE 2022

- INSTRUCTOR: AHMED HANDOUSSA

- NUMBER OF ATTENDEES: 15

- VENUE (1): AMERICAN UNIVERSITY IN CAIRO (AUC), CENTER FOR NANO ELECTRONICS AND DEVICES (CND)

- VENUE (2): TOP MASTER COWORKING SPACE

- WORKSHOP FEES PER PERSON: 2,500 EGP

- INSTRUCTOR LANGUAGE: MAINLY ENGLISH

FOR REGISTRATION & INQUIRIES

- ENG.DALIA MEGAHED: +20 111 112 0672

- ENG.AHMED HOSSAM: +20 111 957 8759

- MRS.SHAIMAA MOHSEN: +20 1008215007

- INFO@EMPOWER-SYS.com

- FACEBOOK PAGE

- LINKEDIN PAGE

- YOUTUBE CHANNEL

ABOUT THE WORKSHOP

EMPOWER ENERGY SYSTEMS (S.A.E) OFFERS THIS WORKSHOP IS PART OF A SERIES OF PRACTICAL INDUSTRIAL WORKSHOPS THAT ARE DESIGNED TO FILL IN THE MISSING LINKS IN THE MARKET.

THEY ARE DESIGNED TO HELP STUDENTS OVERCOME THE GAP FROM THEORY TO INDUSTRIAL PRACTICE, A GAP THAT IS ENCOUNTERED BY ALL FRESH GRADUATES. FURTHERMORE, SOMETIMES TECHNICIANS DESIRE TO INCREASE THEIR KNOWLEDGE OR IMPROVE THEIR SKILLS AND COULD NOT FIND THE RIGHT PLACE TO DO SO. ADDITIONALLY, ENGINEERS NEED TO LEARN INDUSTRIAL SKILLS CONSTANTLY AND DO NOT ALWAYS FIND THE RIGHT PLACE TO SEEK THE INFORMATION OR DO NOT FIND THE RIGHT INFORMATION.

EMPOWER ENERGY SYSTEMS (S.A.E) BRIDGES ALL OF THOSE GAPS THROUGH THE PROPOSED WORKSHOPS.

INDUSTRIAL AUTOMATION

INDUSTRIAL AUTOMATION IS THE DISCIPLINE OF EMPLOYING HARDWARE AND SOFTWARE TO CONTROL, MONITOR AND MANAGE MACHINES EFFICIENTLY AND REDUNDANTLY WITHOUT HUMAN INTERVENTION. IT ENSURES AN TIMELY, ACCURATE AND SAFE PROCESS WITH MINIMUM OPERATIONAL COSTS.

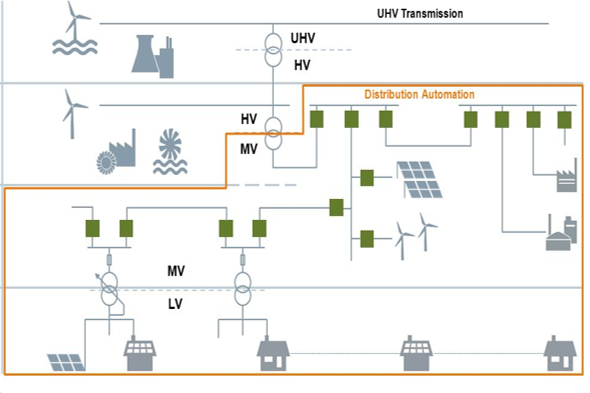

THERE ARE TWO MAJOR CATEGORIES OF AUTOMATION, NAMELY PROCESS AUTOMATION AND DISTRIBUTION AUTOMATION. PROCESS AUTOMATION IS INVOLVED IN CONTROLLING LOADS, MAINLY MACHINES WHILE DISTRIBUTION AUTOMATION IS MORE CONCERNED WITH THE ENERGY DISTRIBUTION DEVICES SUCH AS THE ELECTRICITY SOURCES AND THEIR APPARATUS.

EES MARKET PROMOTION

EMPOWER ENERGY SYSTEMS (EES) S.A.E BELIEVES IN TEAM BUILDING, MARKET PROMOTION AND WIN-WIN SITUATIONS. ACCORDINGLY, WE HELP ENGINEERING STUDENTS, ENGINEERS, AND TECHNICIANS ACQUIRE THE MISSING INDUSTRIAL LINKS AND EXPERIENCES AND AID THEM THROUGHOUT THEIR CAREERS THROUGHOUT OUR WORKSHOPS AND INDUSTRIAL-LEVEL TAILORED PROGRAMS.

WE TRANSFER THE PRACTICAL EXPERIENCE WE ACQUIRE FORM THE FIELD TO THE KEY MARKET PERSONS TO PROMOTE THE TECHNICAL KNOWLEDGE IN THE MARKET AND ACCELERATE IT’S GROWTH.

BENEFIT TO ELECTRONICS ENGINEERS

THE WORKSHOP IS MAINLY BASED UPON ELECTRICAL ENGINEERING PRINCIPLES, IN ITS CORE ESSENCE IT FOCUSES ON THE PRINCIPLES OF ELECTRONICS AND THE APPLICATION OF ELECTRONIC THEORIES IN THE FIELD OF AUTOMATION AND CONTROL OF INDUSTRIAL PROCESSES.

THE WORKSHOP IS ALSO INTEGRAL TO MECHANICAL AND PROCESS ENGINEERS DIRECTLY INVOLVED IN INDUSTRIAL PROCESSES.

WORKSHOP ELIGIBILITY

- ONLY FOR ENGINEERING STUDENTS, ENGINEERS AND TECHNICIANS

- HAVE A THEORETICAL AND PRACTICAL BACKGROUND IN ELECTRICAL ENGINEERING

- GOOD KNOWLEDGE OF ENGLISH

WORKSHOP PREPARATIONS

- OWN YOUR LAPTOP WITH MICROSOFT WINDOWS 10 OR 11 AS THE OPERATING SYSTEM

- YOUR LAPTOP SHOULD PREFERABLY HAVE A CD-ROM DRIVE TO INSTALL SOFTWARE, AN RJ45 ETHERNET PORT AND A WORKING WIRELESS ADAPTOR

- RESERVE SUFFICIENT SPACE ON YOUR LAPTOP (~200 MB) FOR SOFTWARE INSTALLATION

- KINDLY SUBMIT YOUR COVID-19 VACCINATION CERTIFICATE NO MORE THAN THREE DAYS PRIOR TO THE SESSIONS

WORKSHOP REGULATIONS

- ATTEND ON-TIME

- NO SMOKING INSIDE THE UNIVERSITY

- FEEL FREE TO ASK QUESTIONS

- AT THE END OF THE WORKSHOP, YOU MUST PASS AN EXAM AND GET OVER 70% OF THE MARKS CORRECT

- THE EXAM COULD BE ORAL, WRITTEN, OR PRACTICAL

- ATTENDING LATE WILL REDUCE YOUR INTAKE FROM THE WORKSHOP AS THE INFORMATION WILL NOT BE REPEATED

- DEPENDING ON THE NUMBER OF AUDIENCE AND THEIR BACKGROUND, THE TIMETABLE WILL BE SET

WORKSHOP MODULES

- INTRODUCTION TO INDUSTRIAL CONTROLLERS

- CENTRAL PROCESSING UNIT

- ANALOG TO DIGITAL CONVERTERS (ADC)

- ANALOG INPUTS & OUTPUTS

- DIGITAL INPUTS & OUTPUTS

- HUMAN MACHINE INTERFACE (HMI)

- POWER SUPPLIES

- PROTECTION DEVICES

- DATA ACQUISITION HARDWARE

- SENSORS

- DATA LOGGERS

- COMMUNICATION HARDWARE

- COMMUNICATION PROTOCOLS

- SECURITY

- INTRODUCTION TO INDUSTRIAL CONTROLLERS

- TYPES OF INDUSTRIAL CONTROLLERS

- MICROCONTROLLERS

- MICROPROCESSORS

- LOGIC MODULES

- PROGRAMMABLE LOGIC CONTROLLERS (PLCs)

- REMOTE TERMINAL UNITS (RTUs)

- PROGRAMMING CONTROLLERS

- SCRIPTING

- FUNCTION BLOCKS

- LADDER DIAGRAMS

- INTRODUCTION TO LOGO!

- TECHNICAL SPECIFICATIONS

- OVERVIEW OF LOGO!

- LOGO! FAMILY

- LOGO! MAIN COMPUTING UNIT

- LOGO! ANALOG EXPANSION MODULES

- LOGO! DIGITAL EXPANSION MODULES

- LOGO! EXPANSION LIMITATIONS

- LOGO! WIRED COMMUNICATION MODULES

- LOGO! WIRELESS COMMUNICATION MODULES

- TYPES OF LOGO!

- ENERGIZING LOGO! FOR THE 1ST TIME

- INTERACTING WITH LOGO! USING THE SOFTKEYS

- NAVIGATING THE MAIN MENU

- CONFIGURING THE NETWORK PARAMETERS

- STARTING AND STOPPING A PROGRAM

- INSPECTING THE STATUS OF THE INPUTS, OUTPUTS AND FLAGS

- INTERACTING WITH LOGO! USING LOGO! COMFORTSOFT

- ONLINE SETTINGS

- OFFLINE SETTINGS

- FUNCTION BLOCK PROGRAMMING

- LADDER PROGRAMMING

- READ & WRITE PROGRAMS

- ONLINE CONNECTIVITY

- SIMULATION

- PROGRAM BUILDING BLOCKS

- INPUTS & OUTPUTS

- HIGH & LOW SIGNALS

- TIMERS

- FLAGS

- LOGIC FUNCTIONS

- ANALOG FUNCTIONS

- RELAYS

- DISPLAY SCREEN

- SPECIAL PROGRAMS

- COUNTER

- ACTIVATE OUTPUT USING ANALOG SIGNAL

- CASCADED TIMERS

- COMMUNICATING WITH LOGO! USING MODBUS TCP

- INTRODUCTION TO MODBUS TCP

- READ A DISCRETE INPUT

- WRITE TO AN OUTPUT COIL

- READ A HOLDING REGISTER

- WRITE TO A HOLDING REGISTER

- INTERFACING A PRESSURE SENSOR WITH LOGO!

- INTERFACING A TEMPERATURE SENSOR WITH LOGO!

- PROCESS AUTOMATION APPLICATIONS USING A SOFTSTARTER

- SOFTSTARTER ON/OFF CONTROL

- CONTROL OF THE NUMBER OF STARTS

- CONTROL THE TIME INTERVAL BETWEEN SUCCESSIVE STARTS

- MONITORING OF THE SOFTSTARTER OUTPUT CURRENT

- PROCESS AUTOMATION APPLICATIONS USING AN AC DRIVE

- CONTROL OF AN AC DRIVE USING LOGO!

- DISTRIBUTION AUTOMATION APPLICATIONS USING LOGO!

- SOLAR PV APPLICATIONS USING LOGO!

JOIN US NOW

WE WOULD LIKE TO PROVIDE FACULTY AND STUDENTS AN EXCLUSIVE 20% DISCOUNT FOR ATTENDING THE WORKSHOP. THEREFORE, THOSE WHO WISH TO JOIN MUST: -

- BE A CURRENT FACULTY MEMBER OR STUDENT

- AN IDENTIFICATION CARD OR PROOF OF ENROLLMENT

- CONTACT THE FOLLOWING NUMBERS +20 100 821 5007 / +201119578759 / +20 111 112 0672 / +20 100 166 11 37

- DROP US AN EMAILTRAINING@EMPOWER-SYS.com

- VISIT OUR FACEBOOK PAGE

- VISIT OUR LINKEDIN PAGE

- VISIT OUR YOUTUBE CHANNEL